Abstract

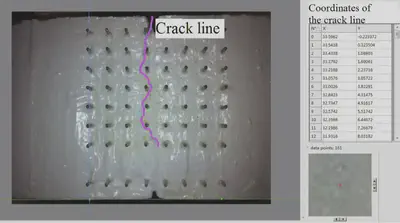

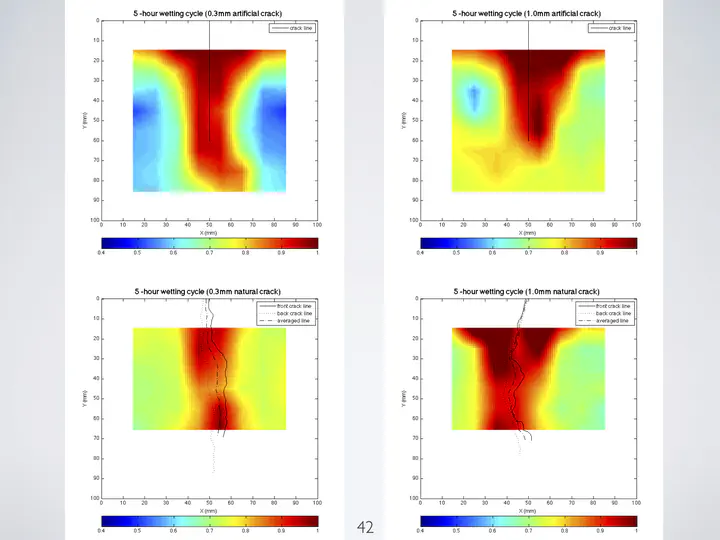

Cracks in reinforced concrete structures can occur as a result of many phenomena such as fresh concrete bleeding, restrained shrinkage, thermal gradients, freeze-thaw cycles, alkali-aggregate reactions, and can also be induced by external loading. Thus, concrete becomes more vulnerable to the processes of deterioration by corrosion of reinforcement. The corrosion rate of cracked reinforced concrete in different exposure conditions has been studied by some researchers. However, it is not clear how the presence of cracks affects the corrosion-determining factors, which control the corrosion pattern at the crack. The objective of this project was to develop an understanding of the effects of cracking on the transport characteristics under wetting and drying cycles. In this project, flexural loading induced natural cracks, and parallel-wall artificial cracks were studied. The infiltration properties of those cracks were evaluated by the tension infiltrometry technique. The saturation conditions around the crack were monitored with the Time Domain Reflectometry (TDR) technique. A numerical simulation was carried out to model the evolution of saturation in the cracked beams; in the model two crack modeling approaches were employed and compared. The infiltration test showed that the presence of both artificial and natural cracks (0.3 mm and 1.0 mm) dramatically increased the permeability of concrete. The value of hydraulic conductivity was increased by up to 5 orders of magnitude at the location of the crack. The evolution of water saturation of the cracked concrete under wetting and drying conditions was analyzed as colour-scaled images and the water saturation contours were compared for different crack openings. For the artificial crack samples, a deviation from the expected “perfectly symmetric” flow regime around a straight crack was observed. This was probably caused by the micro cracks induced during the shim pull-out process or a non-uniform compaction around the shim insertion. For the natural cracks, in the drying phase, smaller cracks seemed to have better water storage. Hence, the water saturation decreased at a slightly slower rate. The crack behaved like an open surface that was exposed to the environment. Application of the same material properties to the open surface and the crack surface did not bring a large error for the water flow simulations. A hysteresis phenomenon has been found during the identification of the Van Genuchten material parameters using an inverse modelling approach, with Ks=5×10-10 cm/s, α =4.33×10-4, for the wetting phase, n=1.32 and for the drying phase, n=2.0. The simulation results suggest that for the simple flexural crack, the 1D crack line averaged from the front and back crack lines is capable of representing the crack in the wetting and drying scenario. The crack could be modelled as “free surface” or “equivalent porous medium”.

Gallery