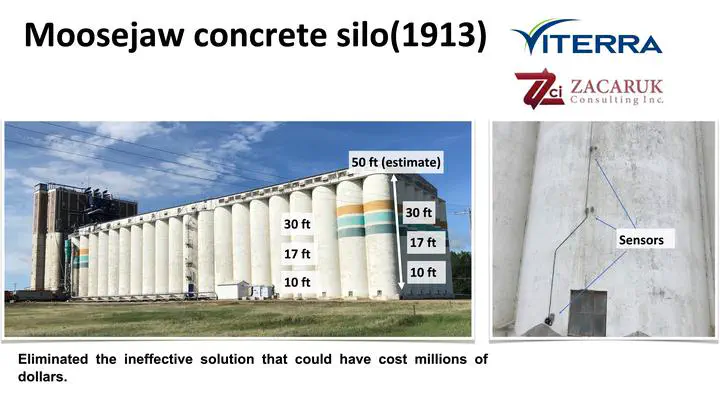

Moose Jaw Inland Grain Terminal Assessment

Built in 1910, the Moose Jaw Inland Grain Terminal stands as a multi-cellular, concrete-constructed grain facility. Recent evaluations hinted at potential corrosion from concrete carbonation, prompting a proposal for extensive rehabilitation.

In our intervention:

- Sensor Placement:

We strategically placed moisture sensors at nine specific points around the terminal’s exterior. Coring was performed at the same spots to ascertain carbonation depth.

- Advanced Modeling:

Leveraging probabilistic models, we predicted concrete silo wall deterioration. Our models factored in site-specific data such as concrete strength, cover thickness, moisture content, and historical weather data.

- Critical Findings:

While carbonation was deeper inside the walls than outside, suggesting conditions ripe for rebar corrosion, actual rebar deterioration was minimal due to the low moisture content.

- Valuable Outcomes:

Predictive analytics forecasted a mere 0.1 mm section loss in the reinforcement by 2071. With this insight, the terminal owners averted a costly, largely ineffective repair, pivoting instead to a visually evidence-based maintenance approach.

Through our detailed analysis and prediction, we offered an efficient alternative to unnecessary multi-million-dollar repairs, emphasizing cost-effectiveness and evidence-driven decision-making.